Quick guide to Hardware Asset Tagging

Martin Thompson and I were recently commissioned to write an overview of options for Hardware Asset Tagging for a client. The client has kindly let us share our report for the benefit of the ITAM Review community. Thanks to Michael Smith, Practice Area and Delivery Manager, Inventory Group at American Appraisal for his peer review and contributions to this guide. If you have any other information to add to this guide about Asset Tagging please contact us or leave a comment, thanks, David.

Asset Tagging Options

Asset Tagging Options

By David Foxen and Martin Thompson, The ITAM Review.

Executive Summary

Whilst hardware is becoming increasingly commoditized at the desk side level; in the datacentre server, storage, network and infrastructure hardware assets still require significant capital investment and extensive maintenance cost for any organization. Additionally, asset loss, business or workflow interruptions and data breaches remain a serious risk. Tracking and managing these assets in the datacentre as efficiently as possible is critical to business operations and maximum return on investment.

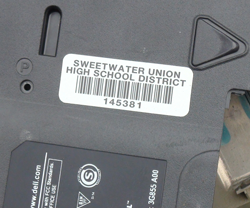

Asset Tagging, and the corollary activity of associating accurate data to the asset tag, is a practice for managing and reconciling ownership, location and configuration of hardware assets. This short paper outlines key approaches to Asset Tagging, some considerations for implementations and strengths and weaknesses of each methodology.

Overall, depending on the unique requirements of organizations, barcodes with embedded RFID are the most robust and efficient method to asset tag.

Options Summary

Asset Tagging is the main process for identifying and managing hardware assets. Asset Tagging has come a long way from simply adding a sticker highlighting the machine name, user and location. There are now a number of different options organisations have for tagging their assets:

|

Approach

|

Explanation |

Strengths |

Weaknesses |

Conclusion |

| Barcoding with RFID | Asset tag with a both a barcode and RFID solution. Asset tags are available as a security tag. | – Secure- Quick- Mature system- Efficient- Real or near real time data collection capability | – Requires new ITAM processes- Requires management of asset database- Requires new hardware and software- Relatively high cost- Radio spectrum usages vary worldwide | Scanner and software required.Best option for efficient Asset ManagementWorks best in a controlled, limited environment |

| Manual asset tags | Creating internal labels and naming conventions | – Low cost option | – Manual- Time consuming- Quality of labels typically is low- Immature- Room for error- Process variances between locations introduce uncertainty | Manual task. Time consuming and resource intensiveLow quality tags not durable |

| Barcoding only | Adding asset tags with unique barcodes | – Reasonably Secure – Can report to inventory/database – Enables better management- Relatively low cost |

– No RFID, so less secure – Requires management of asset database – Updated ITAM processes- Requires labour intensive manual scanning of individual assets after deployed. |

Good option, but not as good as barcodes with RFIDWorks well in a distributed, less controlled environment |

| Serial Numbers | Asset tagging via hardware serial number. Manual entry to database required | – Uses unique serial number identified by vendor- Better management than manual asset tags | – Still manual- S/N’s can rub off- Not all serial numbers are barcoded and subject to human error when input manually- Serial numbers are not always accessible on deployed assets- Doesn’t help manage assets location

– Prone to duplicates / vendor errors

|

Not sophisticated enough, prone to errorSerial number is not a good primary key for databases because of the inconsistent formats and structure between manufacturers. |

Best option

RFID and barcoding (as one solution).

Serial numbers are often duplicated, damaged or not available during the inventory process. The format of the serial number varies widely by manufacturer, which is not conducive to a database key identifier. Serial number collection is prone to human error and interpretation. Serial numbers often have special non-alpha or non-numeric characters (#, -, %). While the serial number is a key data point for all assets, it should not be used as the standard data point for tracking and reporting purposes in isolation. Barcoding is the preferred route. This allows for a consistent, key identifier for all assets in a standard format. Bar coding also allows for a more controlled inventory. Tags can be tracked and assets visually confirmed as well as being captured within the inventory.

RFID asset tags are becoming more standard in the datacentre and server environment, and also with other assets that organisations don’t want to leave the premises. Overall, having an RFID and Barcoded asset tagging solution will bring greater management and security to hardware assets.

Types of RFID

Passive

Passive RFID systems have the reader and reader antenna send a radio signal to the asset tag. The RFID tag then uses the transmitted signal to power on, and reflect energy back to the reader. This form of RFID system can operate in the low frequency (LF), high frequency (HF) or ultra-high frequency (UHF) radio bands.

As passive system ranges are limited by power, they typically have a range of 10m or less, possibly due to positioning and physical obstacles. Due to the fact passive tags do not require a power source or transmitter, and only require a tag chip and antenna, they are cheaper, smaller, and easier to manufacture than active tags. Passive tags should not be placed directly on metal surfaces unless there is foam backing on the tag as the metal may interfere with the return signal.

Passive tags can be packaged in many different ways. They can be sandwiched between an adhesive layer and a paper label to create smart RFID labels. Passive tags may also be embedded in a variety of devices or packages to make the tag resistant to extreme temperatures or harsh chemicals.

Active

In active RFID systems, tags have their own transmitter and power source. Usually, the power source is a battery (see BAP below). Active tags broadcast their own signal to transmit the information stored on their microchips.

Active RFID systems operate in the ultra-high frequency (UHF) band and offer quite a long range to around 100m. This form of active tag is used on valuable objects, such as laptops and mobile devices that need to be tracked over distance. Though the battery life spans have improved considerably, the battery will fail and the tag may ultimately need to be replaced depending on the life of the asset. Active tags will typically have a small rate of failure at initial deployment as well.

You can get active asset tags in two forms. Option one is a transponder (a solution that effectively ‘wakes up’ when it receives a radio transmission for a reader) and option two is beacons (real-time location service that tracks exactly where the asset is). Apart from the feature differences, beacons are not powered by the reader’s signal. They send and receive signals at set intervals instead, based on how often they are required to report back the intervals can be set as low as every few seconds.

BAP (Battery assisted passive systems)

BAP is a battery assisted passive tag, and is an asset tag that uses its own integrated power source. Other RFID solutions use energy from the RFIDs signal to power the asset tags chip. However, BAP tags do not have their own transmitters like other solutions.

Tracking RFID

There are two main methods (also best practice standards) for tracking assets that have an RFID solution:

Indoor RFID’s

Indoor RFID’s use passive systems that can be used over short distances in which the asset needs to be tracked. The asset can be tracked through a small number of known points within the location of the organisation, especially at entry/exit portals, and with an RFID system the asset is automatically monitored. This would be a good solution for desktops and servers. Mobile hand held readers or antennas mounted to carts also offers a sound and efficient way to scan in the RFID tags.

Active RFID provides superior performance where real-time tracking is required throughout a larger or more complex area, such as a large building with many floors, rooms and generally a bigger area. Battery powered active tags have far greater signal range, and certain features of the active RFID are cheaper which makes this a financially more attractive option.

Outdoor GPS Tracking

For assets that will leave the premises, the standard form of asset tracking is via GPS. There are combined RFID and GPS solutions available that provide visibility on assets location when it leaves the office. Such solutions can provide specialist software that help track assets that leave the premises in real-time data. This form of solution also helps with security as if an asset is stolen, data can be remotely wiped form the asset remotely.

These GPS & RFID systems can be configured to highlight key information that an organisation needs, so it’s quite customizable and relevant to any form of organisation.

Key terms

- Asset Tags – are attached to both movable and fixed assets for useful life identification, inventory control and CMMS systems.

- Foil Asset Tags – Made of 100% aluminium with graphics sealed into an anodized layer create a remarkably durable asset label. These tags will often outlast your assets

- High Temperature Asset Tags – Used for assets that are in temperature sensitive locations

- Voiding Asset Tags – Asset tag that destroys itself should it be ripped off. Also leaves ‘void’ imprint on the machine

- Security Labels – removal from any surface leaves a permanent void pattern on the label. Should the asset be removed or stolen, the device will always have the pattern imprinted on it

- Assets – the management of the physical components of computers and networks from procurement through to disposal

- Barcodes –printed onto an Asset Tag to identify items and enable automatic recognition by optical scanners to remove the manual aspect of asset management. Barcodes enable digital scanning of alphabetic and numeric characters and symbols into computer databases.

- CMMS – (Computerized Maintenance Management Systems) – schedule, track and monitor maintenance activities to provide cost, component item, personnel and all reporting history. This is a system for actually managing the assets once they’ve been scanned to the inventory.

- Decoders – Barcode Decoders are more commonly known as barcode scanners or Barcode Readers. They read and convert barcodes used on Asset Labels into digital ID numbers, recognize the encoded data and check it against a database to identify the tagged items they have decoded.

- HAM – Hardware Asset Management

- ITAM – IT Asset Management

- MDM – Mobile Device Management

- RFID (Radio Frequency Identification) – wireless non-contact use of a radio frequency to transfer data to automatically identify and track tags attached to assets. The tags contain electronically stored information.

- SAM – Software Asset Management

Scenarios

Without Asset Tagging

Asset Management –

- No way of identifying assets easily and quickly

- Lack of asset knowledge

- Lack of standardization

- Complicates spot audits, cycle and full inventories

Security issues –

- No way of knowing if a machine has left the premises/organisation or been stolen

- No way of tracking proper environmental disposal at end of life.

With standardised Asset Tagging

Benefits of Asset Tagging

- Better management of assets

- Track the location of assets

- Helps plan and identify assets that require repair or replacement

- Helps maximize employee and equipment efficiency

- Helps reduce equipment downtime through better asset management and planning

- Enhances security of assets

- Assists with hardware compliancy and hardware processes

- Cost savings on hardware and maintenance

- Enhanced asset life cycle management and processes

- Standardized key field identification for easy reference in a standard database repository

The Issues that Asset Tagging Addresses

- Identify unauthorized moves, adds or changes (e.g. server moved from one rack to another without authorization / change request)

- Identify unauthorized changes in configuration (e.g. Memory added or removed from a server without authorization / change request)

- Weak management controls (e.g. No idea what the server does or who it belongs to)

- Weak Asset Disposal processes (e.g. Ensuring the right equipment of the right configuration is actually disposed and no leakages occur)

- Identify devices that have gone missing (e.g. Identify holes in inventory processes for devices that have been removed)

- It is not recommended to add corollary data to the physical asset tag (i.e. some companies add serial, model, department, help desk number, etc.) as this limits the flexibility in tagging the assets initially and adds a great deal of logistics to support the data on the tags. Add on or trailing data is best linked back to a data base repository where it can be managed and updated more easily.

- Consistency and governance

Implementation considerations

Short-term

There are a number of factors to consider when implementing a standardised asset tagging solution:

- Identifying the minimum value of an asset that is required to be tagged

- Identifying mission critical asset that is required to be tagged.

- Removing old, non-standardized asset tagging system

- Auditing current hardware assets to ensure the asset tagging system is completely updated

- Setting up inventory for asset tags to ‘report’ to

- Physically adding the asset tags to the assets

- Collecting, associating or mapping accurate trailing data to the asset tag in some data base repository (precise location, department, ownership, usage, description, type, serial, etc.)

- Reconciling existing data against the new inventory data for process gaps

Long-term

Long-term considerations that must be addressed are:

- Processes need to be implemented companywide to ensure new asset tags are added and managed correctly

- Will asset tags be purchased from a supplier, which is most recommended, or will software and printers be required to print own asset tags?

- On-going management of assets and asset tags. Resources and processes in place?

- Easily identified by all serving partners such as break fix, service desk, and all employees.

ITAM Integration

Asset tagging has an effect on Hardware Asset Management (HAM), Software Asset Management (SAM) and Mobile Device Management (MDM) processes.

HAM;

- With asset tagging in place, hardware lifecycle processes need to be updated to align itself with the new technology used

- Due to the additional information, forecasting budgets for hardware will be easier and more efficient

- Processes for HAM will need to include managing the accompanying software to the asset tag technology

- On average, only 80% of the assets are connected to the network at one time. Idle assets, storage and offline assets make up 20% of the technology environment

- Non-PC assets such as high end monitors, printers, network gear, storage, and voice are not always picked up through discovery alone and need physical tagging and verification if they are to be tracked.

SAM;

- With better HAM management comes better SAM management. Able to align software asset management processes with the new, updated hardware asset management processes

- Able to identify hardware that is unable to run the latest software

- Helps with the software asset lifecycle process

- As with HAM, also helps save on software spend

- Identifies idle or storage assets for licence compliance and repurposing

MDM;

- Tagging and management of the MDM devices is required as part of the ITAM process

- Integration with existing MDM solutions (if in place)

- As with other types of assets, asset tagging helps keep a track of portable mobile devices throughout its lifecycle

Systems Integration

Digital Asset Tagging – some organizations record the asset tag number of physical asset tags within the registry of systems or other logical place such as Active Directory to make retrieval possible via auto-discovery and network inventory systems. This also adds a further level of data verification against other data sources when fed into ITAM repositories or SAM tools.

Data Verification Processes – data verification is an important aspect of an Asset Tagging strategy. Industry best practice suggests verification of assets from at least two separate data points (for example checking the barcode and serial number). This is especially important in the Asset Disposal process whereby an accurate and verifiable chain of custody is required to mitigate data breaches and / or meet industry or government regulation.

Implementation Choices

Questions to consider?

- What will we use asset tags for? What purpose will they serve?

- What is the scope of use?

- How will we interact with asset tags throughout the lifecycle of assets? Namely acquisition, storage, deployment, maintenance, audit, retirement. How will we standardize processes across the whole business?

- How do we establish policies and procedures for asset tagging, data collection and data updates to match IMAC activity? How do we track and enforce compliance of said policies and procedures.

- How will we update and verify the accuracy of data?

- What other data sources will we use to verify the accuracy of our asset data and what unique identifier can we use to verify and match both sets of data?

- What opportunities exist to automate and avoid manual entry / duplication of effort?

- How can we integrate asset tagging business intelligence into the rest of the business to provide as much value as possible from the data collected?

- What policies and procedures do we need to think about in the event of a breach? Can they be covered by existing Change Management exceptions or acceptable use policies?

- What devices, training and support will we need to interact with asset tags out in the field and what regional / cultural differences do we need to consider during implementation?

- What assets are to be tagged and not tracked on daily basis, mainly for contract and support maintenance?

Martin Thompson and I were recently commissioned to write an overview of options for Hardware Asset Tagging for a client. The client has kindly let us share our report for the benefit of the ITAM Review community. Thanks to Michael Smith, Practice Area and Delivery Manager, Inventory Group at American Appraisal for his peer review and contributions to this guide. If you have any other information to add to this guide about Asset Tagging please contact us or leave a comment, thanks, David.

Can’t find what you’re looking for?

More from ITAM News & Analysis

-

Broadcom vs Siemens AG - A Brewing Storm

The ongoing legal battle between VMware (under Broadcom ownership) and Siemens is yet another example of why ITAM goes far beyond license compliance and SAM. What might, at first glance, appear to be a licensing dispute, ... -

Shifting Left Together: Embedding ITAM into FinOps Culture

During one of the keynotes at the FinOps X conference in San Diego, JR Storment, Executive Director of the FinOps Foundation, interviewed a senior executive from Salesforce. They discussed the idea of combining the roles of ... -

Addressing the SaaS Data Gap in FinOps FOCUS 2.1

I recently reported on the FinOps Foundation’s inclusion of SaaS and Datacenter in its expanded Cloud+ scope. At that time, I highlighted concerns about getting the myriad SaaS companies to supply FOCUS-compliant billing data. A couple ...

Podcast

ITAM training

Similar Posts

-

The M&S Cyberattack: How IT Asset Management Can Make or Break Your Recovery

Marks & Spencer (M&S), the iconic UK retailer, recently became the latest high-profile victim of a devastating cyberattack. Fellow retailers The Co-Op and Harrods were also attacked. Recent reports suggest the rapid action at the Co-Op ... -

AI in ITAM: Insightful Signals from the Front Line

During our Wisdom Unplugged USA event in New York in March 2025, we engaged ITAM professionals with three targeted polling questions to uncover their current thinking on Artificial Intelligence—what concerns them, where they see opportunity, and ... -

How ISO/IEC 19770-1 Can Help Meet FFIEC Requirements

In the world of ITAM, the regulatory spotlight continues to intensify, especially for financial institutions facing increasing scrutiny from regulatory bodies due to the growing importance of IT in operational resilience, service delivery, and risk management. ... -

An Introduction to Scope 4 Emissions

Executive Summary For ITAM teams, sustainability is a core responsibility and opportunity. Managing hardware, software, and cloud resources now comes with the ability to track, reduce, and report carbon emissions. Understanding emission scopes—from direct operational emissions ...